St. Charles Brotherhood Center

Location

Bexley, Ohio

Owner

St. Charles Preparatory School

Services

Masonry

Type

Masonry on New Addition

Square Footage

80,000 sq ft

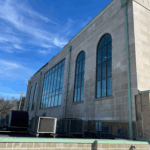

Miles-McClellan Delivers Precision at New Heights with Stonework Above St. Charles Brotherhood Center

Comprehensive Features Include:

- Full masonry work

![]()

The Plan

In honor of its centennial, St. Charles Preparatory School set forth a bold vision in 2022: to build a transformative learning environment that reflects both its rich history and its forward-thinking mission. That vision has taken shape through the construction of the Brotherhood Center, a multi-story academic hub designed to serve generations of students to come and designed to be the new cornerstone of the school’s next 100 years.

Connected to both the Frank E. Murphy ’54 Convocation Center and the Robert C. Walter Student Commons, the Brotherhood Center will serve as an open, collaborative space where students and faculty can come together to learn, innovate and grow. With cutting-edge technology and design, it will be a hub for independent study, creative thinking and community engagement.

The complete Brotherhood center includes ten new classrooms, chemistry and science labs, a media center and library with state-of-the-art technology, collaborative learnings spaces, an amphitheater, a welcome center, an admissions center, a school spirit wear store and a nurse and wellness center.

With structural integrity at the heart of this vision, the project called for exceptional craftsmanship, particularly in its masonry.

The masonry aspects of the project include:

- Help construct a three-story expansion atop a two-story building

- Installing limestone panels with 14,500 lineal feet of Gridworx

- Installation of 20 arches with epoxy and stone

The masonry team at Miles-McClellan was tapped to execute elevated stonework alongside the construction managers at risk CK Construction and the architectural team at Triad Architecture. Our masonry team was brought on board for our reputation for proven mastery across a wide range of commercial and institutional projects, making our team fit to carry out the complex demands of the masonry work required of the project.

The Process

Bringing this intricate, three-story masonry project to life entirely above an active school building required precision, creativity and an unwavering commitment to craftsmanship.

The team installed approximately 10,000 square feet of limestone panels using 14,500 lineal feet of Gridworx channel, a specialized system of metal rails and clips. This solution was necessary due to structural limitations that prevented the use of traditional limestone. Instead, limestone cladding was delivered in pre-fabricated panels — nearly half of the total masonry material — then modified on site as construction conditions evolved.

One of the most visually striking features of the project was the set of 20 arched windows that required delicate kerfing and exact alignment. Installation involved precision epoxy work and square clip fasteners. Because the large window curves left no room for error, our team fabricated custom grinder guides to ensure perfectly straight kerfing, showcasing our attention to detail and fine craftsmanship.

This work unfolded during the coldest months of the year, and many of the Michigan-sourced stone pieces arrived frozen together. To keep the project moving, crews used a heated tent and wet-cutting stations to thaw and separate the stone efficiently. Despite freezing conditions and the fine motor skill required for intricate clipping systems, the team never compromised on quality or safety.

Working from the top down, the masons installed large 200-pound capstones by hand, using chain-and-hook lifts operated by crane. They counted and alternated courses, planned transitions around stacks and arches and ensured alignment and visual consistency throughout.

All installation occurred via five suspended swing stages, which had to be tied back through the completed roof, routed around ductwork and anchored to the finished floor 40 feet below. Despite the complexity and exposure to winter winds, the team maintained tight control over every step.

In some areas, the workspace was extremely constrained. At one point, masons operated from a narrow space between the new addition and an existing bell tower, requiring temporary removal of a piece of roof gutter to allow access. Site logistics added further complexity; material deliveries were challenging due to limited maneuvering space for trucks and offloading equipment. Our team navigated the confined space and consistent material deliveries flawlessly, ensuring a smooth and uninterrupted process.

Safety remained paramount throughout the entirety of Miles-McClellan’s work on the center. Crews were working directly above an active school, with students and staff present daily, requiring the team to implement rigorous site controls and even develop custom protection for a 20’x4’ skylight directly below the work zone to mitigate risks.

This project demanded more than technical skill; it called for foresight, adaptability and the highest level of professionalism. The result is a structure that not only meets functional needs but stands as a testament to what expert masonry can achieve under pressure.

The Proof

“Miles-McClellan has always provided me with a solid team. Their company has been resourceful and are good problem solvers. The team plans their work well and the quality is always top notch.”

– Project Manager at CK Construction

“The project was staffed appropriately, and the project team gave clear and constant communication.”

– Project Manager at CK Construction

“This project demonstrated our masonry team’s ability to operate at the highest level of coordination and craftsmanship. Installing nearly 2,000 stones suspended three stories above an active school in the dead of winter was truly a testament to our dedication to meet our client’s needs and get the job done well.”

– Andy Huff, General Superintendent, Miles-McClellan